EMERALD ECOCHLOR

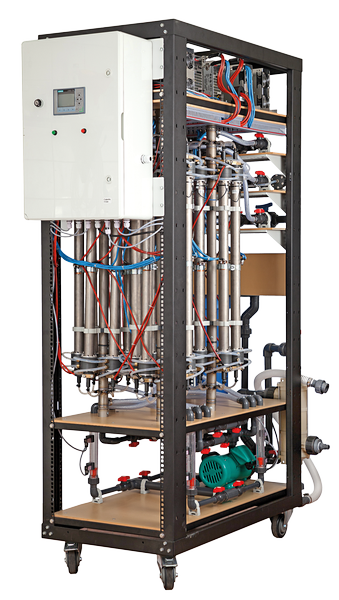

EMERALD ECOCHLOR 3000

Chlorine capacity: 3 kg/hour (72 kg/day).

Sodium hydroxide capacity: 3.4 kg/hour (81.6 kg/day).

Average power consumption: 11.2 kWh.

Advantages:

- Average production cost of 1,000 kg of chlorine gas is at least 1.5 times less than the average cost of chlorine gas sold in cylinders and 2.5 times less than the cost of sodium hypochlorite in FAC terms.

- EMERALD ECOCHLOR devices has a capacity from 0.25 to 3.0 kilograms of chlorine per hour producing wet or dry chlorine gas under pressure and caustic soda solution, eliminating the need for chlorine drying, transportation, storage, as well as the safety and security system for chlorine handling.

- Chlorine in any technology is used in a gaseous state, so ECOCHLOR devices of the required capacity will meet the needs of any enterprise with safe chlorine, yielding caustic soda solution as an additional valuable product.

- The devices do not fall under the licensed type of activity, excluding costs for ensuring industrial safety requirements.

- EMERALD ECOCHLOR devices don’t have replaceable or fast-wearing parts eliminating maintenance costs for traditional membrane electrolysers and regular replacement of NAFION polymer membranes.

Application:

- Chlorine consuming processes in chemical, mining, processing, pharmaceutical, food industries, water treatment, agriculture.

- At metallurgical and chemical enterprises for leaching of rare, non-ferrous and noble metals by hydrochlorination method from ores and wastes to extract gold, silver, copper, platinum, palladium. The advantage is the high chemical activity of chlorine at the time of its formation.

- In uranium mining and processing technology, including the intensification of uranium in-situ leaching (ISL) processes,

regeneration of uranium ISL solutions and the use in liquid radioactive waste treatment technologies. - To dissolve platinum group metals instead of the traditional technology using “aqua regia” (a mixture of concentrated nitric (HNO3) and hydrochloric (HCl) acids), which eliminates the emissions of toxic nitrogen oxides into the atmosphere while obtaining an additional product – caustic soda.

- Yields a 15-20% caustic soda solution (NaOH), which is a valuable co-reagent and is used in various industries: textile, chemical, food, oil, etc.

- Production of 360 liters per day of 20% hydrochloric acid (HCl capacity of one EMERALD ECOCHLOR 3000 device).

Completed projects

6 units of ECOCHLOR devices with a total chlorine capacity of 7 kg/h at chemical-pharmaceutical company Chemstar in Atlanta (USA). No need to dry, transport and store chlorine in cylinders for industrial processes.

One ECOCHLOR 500 device at a manufacturing plant in Miami (USA) for recovering of platinum, rhodium and palladium from spent automotive catalysts enabled recovery of up to 1 kg of platinum per day.

ECOCHLOR 3000 device in uranium ISL intensification processes allows

to increase the uranium recovery rate from basic 70% to 96% using electrochemically activated sorption matrices, NAC Kazatomprom, Kazakhstan, 2022.

Economic feasibility of EMERALD ECOCHLOR devices

| Basic criteria | Values | Notes |

|---|---|---|

| Production cost of 1,000 kg of chlorine | $485 | Average production cost is at least 1.5 times less than the average cost of chlorine gas sold in cylinders and 2.5 times less than the cost of sodium hypochlorite in FAC terms. |

| Power consumption per 1 kg of chlorine | 3.5–4 kW | |

| Table salt consumption per 1 kg of chlorine | 1.8–2 kg | |

| No replaceable or fast-wearing parts | Yes | The main components are durable and resistant to wear and tear. |

| Average payback period (ROI) | 2 years | |

| Average device lifespan | 12 years In total: | 10 years of profit + preserving the Planet’s ecology! |

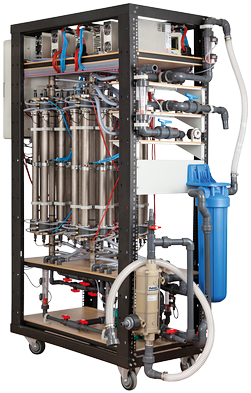

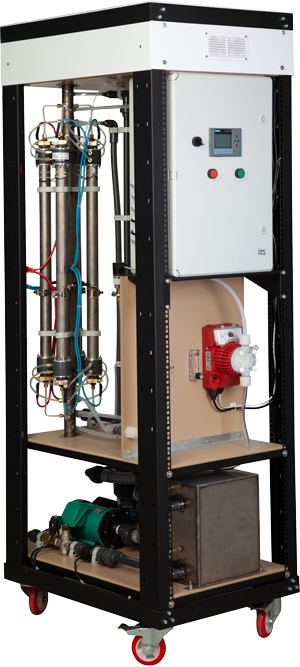

EMERALD ECOCHLOR devices product line

| Model | Chlorine gas capacity (Cl2), g/h | Caustic soda capacity (NaOH), g/h | Power consumption, no more than, W | Table salt consumption (NaCl), no more than, g/h | Dimensions, WxHxD, mm | Net weight, kg |

|---|---|---|---|---|---|---|

| EMERALD ECOCHLOR 250 | 250 | 283 | 1,200 | 500 | 600х1800х800 | 110 |

| EMERALD ECOCHLOR 500 | 500 | 567 | 2,500 | 1,000 | 600х1800х800 | 120 |

| EMERALD ECOCHLOR 1000 | 1,000 | 1,133 | 4,800 | 2,000 | 600х2000х750 | 130 |

| EMERALD ECOCHLOR 1500 | 1,500 | 1,700 | 7,200 | 3,000 | 600х2000х1000 | 150 |

| EMERALD ECOCHLOR 2000 | 2,000 | 2,260 | 9,000 | 4,000 | 700х2000х1150 | 170 |

| EMERALD ECOCHLOR 3000 | 3,000 | 3,400 | 14,500 | 6,000 | 700х2000х1450 | 200 |